-

WHO WE ARE

WHO WE ARE

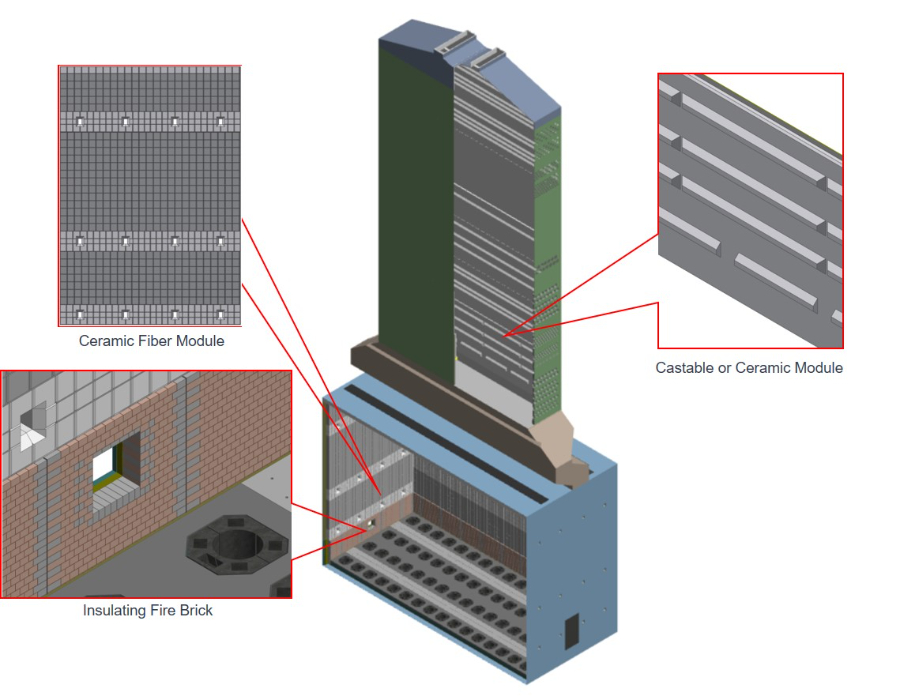

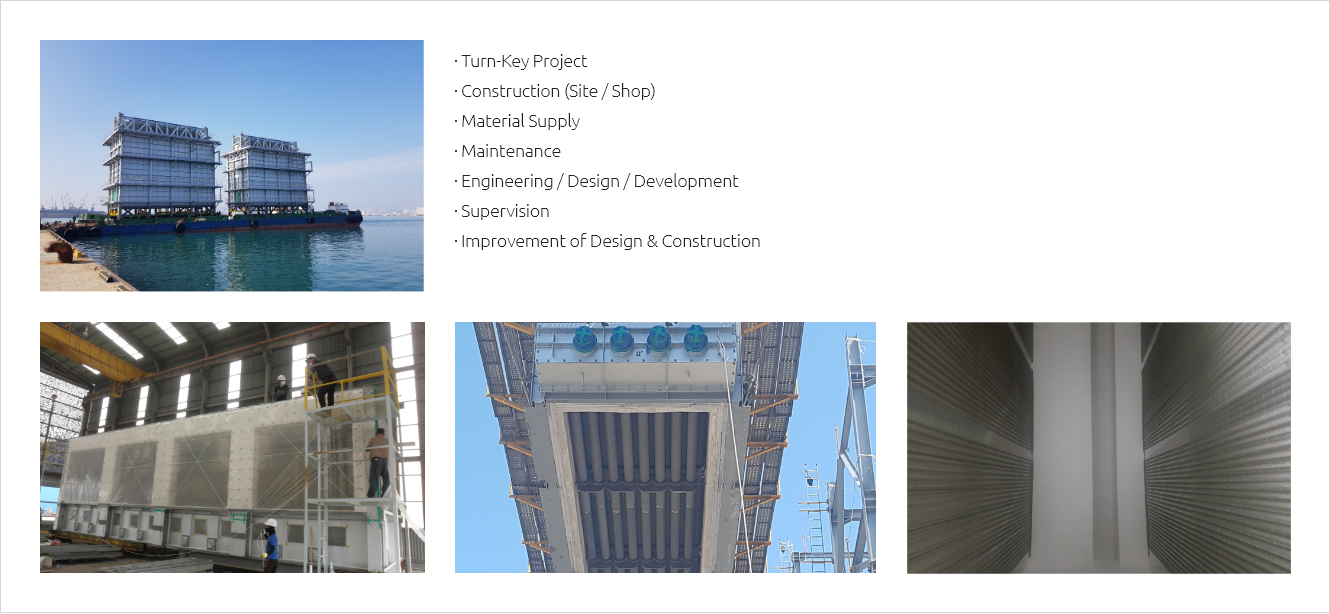

IntroInsulation Korea is growing with you based on the accumulated experience and technology over the past decades with the core value of "Respect, Customer Satisfaction, Customer Happiness" and the vision of "Customer Satisfaction with the Best Technology" with a sense of responsibility as a leader in fire resistance, insulation, fire protection, explosion and eco-friendliness. We will not stay in one place but fly higher with continuous growth. -

WHAT WE DO

WHAT WE DO

IntroInsulation Korea provides

"One packaged total solution" through One Window from A to Z for customer's project development stage based on professional technology by identifying the customer's needs within 48 hours once we receive the RFQ from customers. -

OUR SERVICE

OUR SERVICE

IntroInsulation Korea provides

the world's highest quality fire resistance materials and special materials required for industrial facilities, from 1800β³É high temperature ceramic refractory products to -196β³É cryogenic insulation materials. -

OUR MARKET

OUR MARKET

IntroInsulation Korea goes

beyond the energy sector towards the smart era, from energy saving solutions in industrial plant fields such as petrochemicals, oil refining, and steel, to job training, process management, and safety training combined with 5G communication network and metaverse. -

CONTACTS

CONTACTS

Introby pursuing the value of living together, Insulation Korea respect the aesthetics of sharing. A place where people know the value of being together we, Insulationkkorea tell you the out stories.

- WHO WE ARE

- WHAT WE DO

- OUR SERVICE

- OUR MARKET

- CONTACT

NCC : Ethylene Cracker

Overview

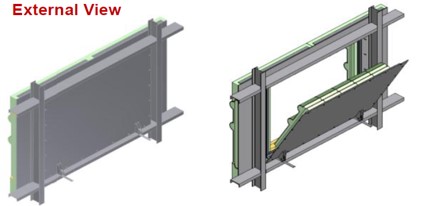

NCC (Naphtha Cracking Center) is a plant that produces petrochemical raw materials such as ethylene, propylene, mixed-C4, and pyrolysis gasoline (PG) by thermally decomposing naphtha at a temperature of 1,000β³É or higher.

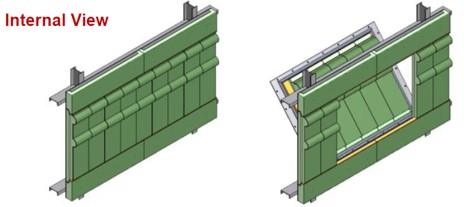

In the Radiant Zone, where high-temperature radiant heat pyrolyzes Naphtha, insulation fire bricks (IFB) and Ceramic Module Lining are applied to maximize the insulation effect, and Naphtha Pre-Heating and convection zone where steam is produced are applied castable which have excellent durability.

Insulation Korea provide high-density ceramic module lining design technology that can maximize the thermal efficiency of the convection part while maintaining castable durability and a special energy saving solution that can be applied to the NCC convection part such as the Carbo-Wall System.

Available Service

Section & Material

βÄΔ Radiant Zone

Section | Lining | Material |

Lower Wall | Insulating Block | Skamopetro S-1100E |

U- Brid | ||

Promasil | ||

Insulating Fire Block | LBK-23 LBK-28 LBK-30 | |

Upper Wall | Ceramic Fiber Blanket | 1260 Blanket, 6P/8P 1430 Blanket, 6P/8P 1430 Ceramic Folded Module |

Arch |

βÄΔ Convection Zone

Location | Lining | Material |

Lower Zone | Ceramic Fiber Blanket | 1260 Ceramic Blanket |

Ceramic Fiber Module | 1430 Ceramic Module (Special Density) | |

Intermediate Zone | Insulating Block | Skamopetro S-1100E |

U-Brid | ||

Promasil | ||

Medium Weuight Insulating Castable | GOLITE 135 | |

LITEWATE MWHT | ||

ECOLITE MW 23 HS | ||

Upper Zone | Insulating Castable | GOLITE 90L |

LITEWATE 800 | ||

ECOLITE 085 HS |

Application

Related

-

SM (STEAM SUPERHEATER)

-

VCM (EDC CRACKER)

-

GTG DUCT

Contacts

INSULATIONKOREA provide total packaged

solutions as one window for whole industries.