CASE STUDY

-

Owner :

Daewoo Engineering & Construction / Jorf Lasfar Energy Company

-

Location :

Douar Oulad Zid, Doukkala-Abda, Morocco

-

Scope of Supply :

Material Supply

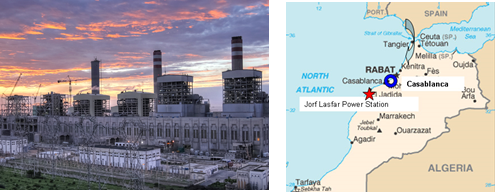

Background

In 2011, a consortium consisting of Mitsui and Daewoo E&C entered into an engineering, procurement and construction (EPC) contract with Jorf Lasfar Energy Company 5&6 ("JLEC 5&6"), for the development of 700MW coal-fired power plant in Morocco.

Mitsui and Daewoo built two new units, each with a gross capacity of 350MW, at the existing Jorf Lasfar power plant site (previously four units each generating 350MW) near El Jadida, as well as installing the first flue-gas desulfurization system in a Moroccan power plant.

-

Project Summary

The contract is valued at approximately 1.1 billion US Dollars, making it one of the largest power plant EPC

projects ever awarded to a Japanese company in North Africa.

Mitsui and Daewoo were able to successfully leverage the competitive advantages of a Japanese-Korean

consortium in order to secure the award of the EPC contract, combining the supply of reliable, high quality core

equipment from Japan, including steam turbines from Mitsubishi Heavy Industries Ltd. and boilers from IHI

Corporation, with the efficiency of Korean engineering and construction works.

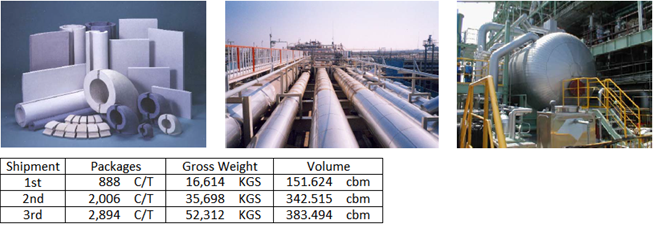

We're awarded for supply of U-BRID by Daewoo E&C in 2013 and all materials were successfully supplied

in three times.

-

Participate as

Material Supply for Unit 5 & 6 Coal-Fired Power Plants

Delivery Scale

Approximately 105 tones of U-Brid For Boiler Piping, BOP Pipes, and 45° & 90° Elbows